Just in time for Halloween and indulging in sweets of all kinds, Special Collections has released a new digital collection documenting the Brock Candy Company, a Chattanooga-based candy manufacturing company that operated in the city for over 100 years. The collection of photographs, originally acquired by the Chattanooga History Center, is now jointly stewarded by UTC Special Collections and the Chattanooga Public Library.

Candy-making has a long history in Chattanooga. During the late 1800s, local businessmen W. Jefferson Dobbs and James N. Trigg opened the Trigg-Dobbs Company, a small wholesale grocery and candy store chain that grew to have several locations in the area. In 1906, William Emerson Brock, Sr., a traveling salesman from North Carolina, acquired the Trigg Candy Company and continued its production of penny candies and bulk and slab candies, such as peanut brittle, peppermints, and fudge. The company was reincorporated in 1909, changing the name to Brock Candy Company. Until the 1960s and 1970s, nearly all of Brock’s candy production took place at their downtown Chattanooga Chestnut Street factory.

While serving as president of Brock Candy, William E. Brock also engaged in business in banking and insurance, and served for many decades as a trustee of the University of Chattanooga. In 1929, Brock was appointed by the governor to fill a seat in the United States Senate left vacant following the death of Senator Lawrence D. Tyson, and was subsequently elected to serve the remainder of the late senator’s term until 1931. William Emerson Brock III, Brock’s grandson, continued the family legacy of political and civic engagement, representing Tennessee’s Third District in the United States House of Representatives from 1963-1971, and as Senator from Tennessee from 1971-1977.

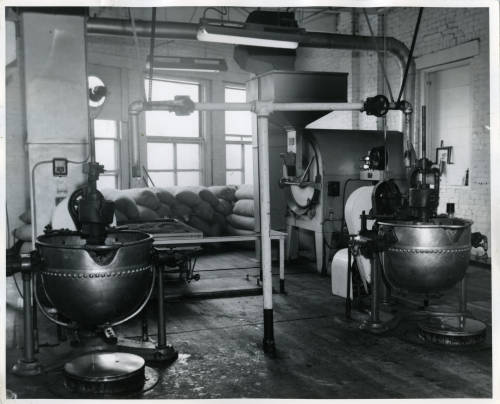

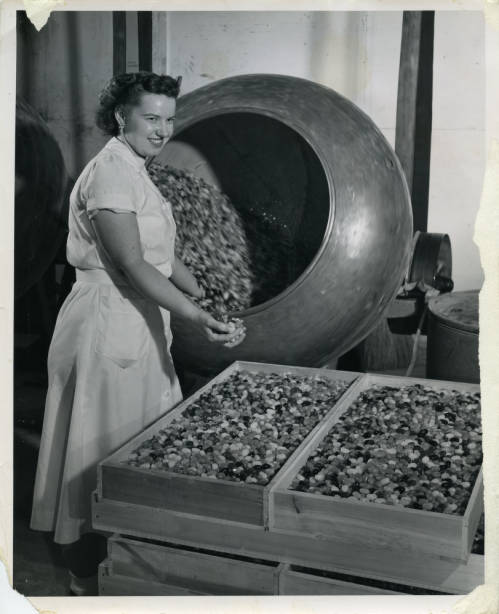

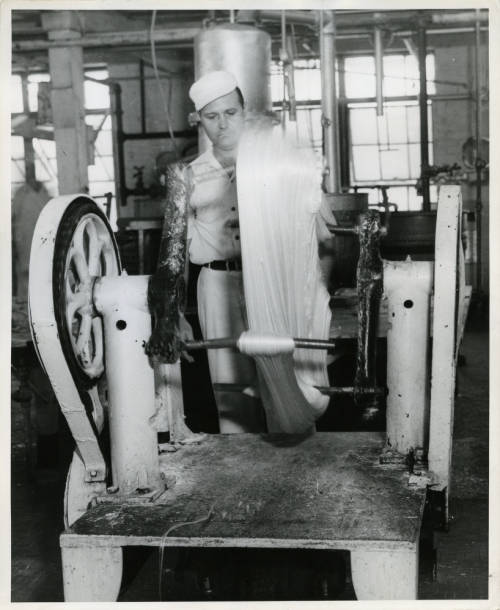

Photographs from inside the Brock Candy factory document the kinds of machinery and processes used to make the company’s signature products. In the 1920s, the company moved away from slab candy production and focused more on soft candies such as jellies and marshmallows (think of candy corn and jelly beans), all of which used a cornstarch tray molding process. The process began with heating and melting sugar and other candy ingredients into a liquid slurry. Trays of cornstarch were prepared by imprinting the desired candy shape, which molded the candy slurry as it cooled and solidified. The candies were then sifted out of the cornstarch and finished in a variety of ways. For jelly beans, they were given a colored hard sugar coating and polished in large drums called dragée pans.

Cornstarch was used around the factory in other ways, too. In a 2018 article for Chattanoogan.com, Terry Reynolds recalled his experiences working at the Brock Candy production plant, where he worked second shift making hard candies. He wrote:

The ambient air temperature in the room was extremely hot so that the near-liquid sugar and corn syrup mixture did not cool too fast…Everything had to be kept covered in corn starch to keep the near-liquid product from sticking to the equipment. The clouds of corn starch swirling around in the room left a white crust around your eyes, nose and mouth as well as any skin that was covered in sweat and exposed.

The images in the Brock Candy Company photographs digital collection give a view of what it looked like on the factory floor and illustrate the hard work and variety of tasks that went into producing a wide range of confections.

The collection of photographs date mainly from the late 1940s to mid-1950s, a time when the company was marketing a new product, the Brock Bar. With the institution of sugar rationing during World War II, Brock Candy was forced to cut back much of its usual production and adapt to producing candies with ingredients that were still abundantly available, such as corn syrup and peanuts. A result of these adaptations, the Brock Bar, a chocolate-coated, peanut and caramel roll, became one of the company’s signature products.

Brock Candy continued to expand throughout the second half of the 20th century, opening a second production plant in the Shallowford area of Chattanooga on Jersey Pike, and acquiring two other candy companies, Schuler Chocolates in Minnesota and Shelly Brothers, Inc. in Pennsylvania. In 1981, Brock Candy became one of the first American companies to produce European-style gummy candies, and began introducing more fruit-based snacks and candies.

The company went public in 1993, and a year later, Brock Candy was acquired by Chicago-based company Brach Confections. Production of jelly candies and fruit snacks continued at the Chattanooga plant on Jersey Pike for the next two decades. The company was sold to Farley’s & Sathers Candy Company in 2007, which in turn merged with Ferrara Pan Candy Company to become Ferrara Candy Company in 2012. In 2014, Ferrara Candy closed the Jersey Pike plant, ending over 100 years of Brock Candy production in Chattanooga. While you might not be able to find Brock Bars or Brock chocolate-covered cherries on shelves anymore, Brach’s Candy continues to produce a number of different candies as a subsidiary of Ferrara, and today is the maker of the bestselling candy corn product in the United States!

Credit: All images are provided courtesy of the Chattanooga Public Library and University of Tennessee at Chattanooga Special Collections.